REFERENCE TO A SEQUENCE LISTING

[0001]This application contains a Sequence Listing in computer readable form, which is incorporated herein by reference.

FIELD OF THE INVENTION

[0002]The present invention relates generally to processes for preconditioning pretreated lignocellulose-containing material with a combination of laccase and beta-glucosidase and to processes of enhancing enzymatic hydrolysis using such preconditioned material. The invention also relates to processes for obtaining hydrolysis products and fermentation products, as well as to an enzyme preconditioning composition.

DESCRIPTION OF RELATED ART

[0003]Renewable energy sources provide an alternative to current fossil fuel dependence. Production of ethanol as an energy source includes the basic steps of hydrolysis and fermentation. These steps are integrated within larger processes to obtain ethanol from various source materials. Processes have been developed using sources including starch-based feedstocks, sugars and biomass, including cellulosic feedstocks.

[0004]When the selected feedstock is starch-based, the sugars are readily available and/or accessible for hydrolysis and fermentation. Where biomass is used for production of ethanol, the biomass is generally pretreated to reduce resistance to hydrolysis and fermentation processes. The pretreatment may be performed prior to or subsequent with the hydrolysis and/or fermentation steps, in order to increase the availability of the cellulosic material for those steps. Without this pretreatment, the structural complexity of the biomass will hinder conversion of the cellulosic material to ethanol.

[0005]Current pretreatment processes include physical pretreatment, chemical pretreatment and biological pretreatment, but each of these processes has inherent limitations.

[0006]Pretreatment of biomass can also result in release of byproducts that are undesirable to the process as a whole. Different types of biomass will contain varying amounts of cellulose, hemicellulose, lignin and other components. Pretreatment of the biomass, which is necessary to access the sugars from the cellulose and hemicellulose may also result in production of byproducts that may interfere in the hydrolysis and fermentation steps, resulting in reduced overall process efficiency and ethanol production. Such byproducts may include sugar based oligomers and lignin based inhibitors.

[0007]While laccase has been observed as useful in the detoxification of pretreated corn stover (WO2008134259), additional detoxification processes would be useful to the industry.

[0008]Thus, there remains a need in the art to develop processes for treatment of biomass feedstocks that result in increased availability of cellulosic material for conversion to ethanol and decreased production of undesirable byproducts. The present invention provides such processes.

SUMMARY OF THE INVENTION

[0009]Described herein are processes for preconditioning pretreated lignocellulosic material to improve availability for enzymatic hydrolysis (saccharification). Also described are processes for producing a hydrolysis product and/or a fermentation product from such preconditioned lignocellulosic material. Compositions suitable for use in methods and/or processes of the invention are also described.

[0010]The present invention is based on the surprising discovery that preconditioning of pretreated biomass with a combination of laccase and beta-glucosidase prior to hydrolysis reduces DP2 concentration and lignin-based inhibitors, thereby improving enzyme hydrolysis and increasing glucose yield.

[0011]Thus in one aspect, the invention relates to processes for preconditioning pretreated lignocellulose-containing material, the process comprising incubating the pretreated lignocellulose-containing material with laccase and beta-glucosidase prior to hydrolysis.

[0012]In another aspect, the invention relates to processes for producing a hydrolysis product from lignocellulose-containing material, the processes comprising the steps of preconditioning the lignocellulose-containing material by incubation with laccase and beta-glucosidase, followed by hydrolysis.

[0013]In an additional aspect, the invention relates to processes for producing a fermentation product from lignocellulose-containing material, the processes comprising the steps of preconditioning the lignocellulose-containing material by incubation with laccase and beta-glucosidase, followed by hydrolysis to obtain a hydrolysis product and fermentation of the hydrolysis product to obtain a fermentation product.

[0014]In still another aspect, the invention relates to an enzyme preconditioning composition for the preconditioning of unwashed pretreated fractionated corn fiber, the composition comprising laccase and beta-glucosidase.

DEFINITIONS

Beta-Glucosidase:

[0015]The term “beta-glucosidase” means a beta-D-glucoside glucohydrolase (E.C. 3.2.1.21) that catalyzes the hydrolysis of terminal non-reducing beta-D-glucosyl residues with the release of beta-D-glucose.

[0016]Beta-glucosidase activity may be determined using p-nitrophenyl-beta-D-glucopyranoside as substrate according to the procedure of Venturi et al., 2002, Extracellular beta-D-glucosidase from Chaetomium thermophilum var. coprophilum: production, purification and some biochemical properties, J. Basic Microbiol. 42: 55-66. One unit of beta-glucosidase is defined as 1.0 μmole of p-nitrophenolate anion produced per minute at 25° C., pH 4.8 from 1 mM p-nitrophenyl-beta-D-glucopyranoside as substrate in 50 mM sodium citrate containing 0.01% TWEEN® 20 (polyoxyethylene sorbitan monolaurate).

Cellobiohydrolase:

[0017]The term “cellobiohydrolase” (“CBH”) generally means a 1,4-beta-D-glucan cellobiohydrolase (E.C. 3.2.1.91) that catalyzes the hydrolysis of 1,4-beta-D-glucosidic linkages in cellulose, cellooligosaccharides, or any beta-1,4-linked glucose containing polymer, releasing cellobiose from the reducing or non-reducing ends of the chain (Teeri, 1997, Crystalline cellulose degradation: New insight into the function of cellobiohydrolases, Trends in Biotechnology 15: 160-167; Teeri et al., 1998, Trichoderma reesei cellobiohydrolases: why so efficient on crystalline cellulose?, Biochem. Soc. Trans. 26: 173-178).

[0018]Cellobiohydrolase activity is determined according to the procedures described by Lever et al., 1972, Anal. Biochem. 47: 273-279; van Tilbeurgh et al., 1982, FEBS Letters, 149: 152-156; van Tilbeurgh and Claeyssens, 1985, FEBS Letters, 187: 283-288; and Tomme et al., 1988, Eur. J. Biochem. 170: 575-581. In the present invention, the Tomme et al. method can be used to determine cellobiohydrolase activity.

Cellulolytic Enzyme Preparation, Cellulolytic Composition, or Cellulase:

[0019]The term “cellulolytic enzyme preparation”, “cellulolytic composition”, or “cellulase” means one or more (e.g., several) enzymes that hydrolyze a cellulosic material. Such enzymes include endoglucanase(s), cellobiohydrolase(s), beta-glucosidase(s), or combinations thereof. The two basic approaches for measuring cellulolytic activity include: (1) measuring the total cellulolytic activity, and (2) measuring the individual cellulolytic activities (endoglucanases, cellobiohydrolases, and beta-glucosidases) as reviewed in Zhang et al., Outlook for cellulase improvement: Screening and selection strategies, 2006, Biotechnology Advances 24: 452-481. Total cellulolytic activity is usually measured using insoluble substrates, including Whatman No 1 filter paper, microcrystalline cellulose, bacterial cellulose, algal cellulose, cotton, pretreated lignocellulose, etc. The most common total cellulolytic activity assay is the filter paper assay using Whatman No 1 filter paper as the substrate. The assay was established by the International Union of Pure and Applied Chemistry (IUPAC) (Ghose, 1987, Measurement of cellulase activities, Pure Appl. Chem. 59: 257-68).

[0020]Cellulolytic enzyme activity is determined by measuring the increase in hydrolysis of a cellulosic material by cellulolytic enzyme(s) under the following conditions: 1-50 mg of cellulolytic enzyme protein/g of cellulose in Pretreated Corn Stover (“PCS”) (or other pretreated cellulosic material) for 3-7 days at a suitable temperature, e.g., 50° C., 55° C., or 60° C., compared to a control hydrolysis without addition of cellulolytic enzyme protein. Typical conditions are 1 ml reactions, washed or unwashed PCS, 5% insoluble solids, 50 mM sodium acetate pH 5, 1 mM MnSO4, 50° C., 55° C., or 60° C., 72 hours, sugar analysis by AMINEX® HPX-87H column (Bio-Rad Laboratories, Inc., Hercules, Calif., USA).

Hemicellulolytic Enzyme, Hemicellulolytic Enzyme Preparation or Hemicellulase:

[0021]The term “hemicellulolytic enzyme”, “hemicellulolytic enzyme preparation” or “hemicellulase” means one or more (e.g., several) enzymes that hydrolyze a hemicellulosic material. See, for example, Shallom and Shoham, 2003, Current Opinion In Microbiology 6(3): 219-228). Hemicellulases are key components in the degradation of plant biomass. Examples of hemicellulases include, but are not limited to, an acetylmannan esterase, an acetylxylan esterase, an arabinanase, an arabinofuranosidase, a coumaric acid esterase, a feruloyl esterase, a galactosidase, a glucuronidase, a glucuronoyl esterase, a mannanase, a mannosidase, a xylanase, and a xylosidase. The substrates for these enzymes, hemicelluloses, are a heterogeneous group of branched and linear polysaccharides that are bound via hydrogen bonds to the cellulose microfibrils in the plant cell wall, crosslinking them into a robust network. Hemicelluloses are also covalently attached to lignin, forming together with cellulose a highly complex structure. The variable structure and organization of hemicelluloses require the concerted action of many enzymes for its complete degradation. The catalytic modules of hemicellulases are either glycoside hydrolases (GHs) that hydrolyze glycosidic bonds, or carbohydrate esterases (CEs), which hydrolyze ester linkages of acetate or ferulic acid side groups. These catalytic modules, based on homology of their primary sequence, can be assigned into GH and CE families. Some families, with an overall similar fold, can be further grouped into clans, marked alphabetically (e.g., GH-A). A most informative and updated classification of these and other carbohydrate active enzymes is available in the Carbohydrate-Active Enzymes (CAZy) database. Hemicellulolytic enzyme activities can be measured according to Ghose and Bisaria, 1987, Pure & Appl. Chem. 59: 1739-1752, at a suitable temperature such as 40° C.-80° C., e.g., 50° C., 55° C., 60° C., 65° C., or 70° C., and a suitable pH such as 4-9, e.g., 5.0, 5.5, 6.0, 6.5, or 7.0.

Laccase:

[0022]The term “laccase” means an oxidase family enzyme (E.C. 3.2.1.21) that oxidizes phenols and similar molecules.

Mature Polypeptide:

[0023]The term “mature polypeptide” means a polypeptide in its final form following translation and any post-translational modifications, such as N-terminal processing, C-terminal truncation, glycosylation, phosphorylation, etc. For instance, the mature polypeptide may be identified, using, e.g., the SignalP program (Nielsen et al., 1997, Protein Engineering 10: 1-6) that predicts a portion of the amino acid sequence as a signal peptide. As such, the mature polypeptide would be identified as the sequence lacking such redicted signal portion.

[0024]It is known in the art that a host cell may produce a mixture of two of more different mature polypeptides (i.e., with a different C-terminal and/or N-terminal amino acid) expressed by the same polynucleotide.

Mature Polypeptide Coding Sequence:

[0025]The term “mature polypeptide coding sequence” means a polynucleotide that encodes a mature polypeptide having enzyme activity.

Parent Enzyme:

[0026]The term “parent” means an enzyme to which an alteration is made to produce a variant. The parent may be a naturally occurring (wild-type) polypeptide or a variant thereof.

Polypeptide Having Cellulolytic Enhancing Activity:

[0027]The term “polypeptide having cellulolytic enhancing activity” means a polypeptide that catalyzes the enhancement of the hydrolysis of a cellulosic material by enzyme having cellulolytic activity.

[0028]“Auxiliary Activity 9” or “AA9” means a polypeptide classified as a lytic polysaccharide monooxygenase (Quinlan et al., 2011, Proc. Natl. Acad. Sci. USA 208: 15079-15084; Phillips et al., 2011, ACS Chem. Biol. 6: 1399-1406; Lin et al., 2012, Structure 20: 1051-1061). AA9 polypeptides were formerly classified into the glycoside hydrolase Family 61 (GH61) according to Henrissat, 1991, Biochem. J. 280: 309-316, and Henrissat and Bairoch, 1996, Biochem. J. 316: AA9 polypeptides enhance the hydrolysis of a cellulosic material by an enzyme having cellulolytic activity. Cellulolytic enhancing activity may be determined by measuring the increase in reducing sugars or the increase of the total of cellobiose and glucose from the hydrolysis of a cellulosic material by cellulolytic enzyme under the following conditions: 1-50 mg of total protein/g of cellulose in pretreated corn stover (PCS), wherein total protein is comprised of 50-99.5% w/w cellulolytic enzyme protein and 0.5-50% w/w protein of an AA9 polypeptide for 1-7 days at a suitable temperature, such as 40° C.-80° C., e.g., 50° C., 55° C., 60° C., 65° C., or 70° C., and a suitable pH, such as 4-9, e.g., 4.5, 5.0, 5.5, 6.0, 6.5, 7.0, 7.5, 8.0, or 8.5, compared to a control hydrolysis with equal total protein loading without cellulolytic enhancing activity (1-50 mg of cellulolytic protein/g of cellulose in PCS).

[0029]AA9 polypeptide enhancing activity can be determined using a mixture of CELLUCLAST® 1.5L (Novozymes A/S, Bagsærd, Denmark) in the presence of 2-3% of total protein weight Aspergillus oryzae beta-glucosidase (recombinantly produced in Aspergillus oryzae according to WO 02/095014) or 2-3% of total protein weight Aspergillus fumigatus beta-glucosidase (recombinantly produced in Aspergillus oryzae as described in WO 02/095014) of cellulase protein loading is used as the source of the cellulolytic activity.

[0030]AA9 polypeptide enhancing activity can also be determined by incubating an AA9 polypeptide with 0.5% phosphoric acid swollen cellulose (PASC), 100 mM sodium acetate pH 5, 1 mM MnSO4, 0.1% gallic acid, 0.025 mg/ml of Aspergillus fumigatus beta-glucosidase, and 0.01% TRITON® X-100 (4-(1,1,3,3-tetramethylbutyl)phenyl-polyethylene glycol) for 24-96 hours at 40° C. followed by determination of the glucose released from the PASC

[0031]AA9 polypeptide enhancing activity can also be determined according to WO 2013/028928 for high temperature compositions.

[0032]AA9 polypeptides enhance the hydrolysis of a cellulosic material catalyzed by enzyme having cellulolytic activity by reducing the amount of cellulolytic enzyme required to reach the same degree of hydrolysis preferably at least 1.01-fold, e.g., at least 1.05-fold, at least 1.10-fold, at least 1.25-fold, at least 1.5-fold, at least 2-fold, at least 3-fold, at least 4-fold, at least 5-fold, at least 10-fold, or at least 20-fold.

Variant:

[0033]The term “variant” means a polypeptide having enzyme or enzyme enhancing activity comprising an alteration, i.e., a substitution, insertion, and/or deletion, at one or more (e.g., several) positions. A substitution means replacement of the amino acid occupying a position with a different amino acid; a deletion means removal of the amino acid occupying a position; and an insertion means adding an amino acid adjacent to and immediately following the amino acid occupying a position.

Wild-Type Enzyme:

[0034]The term “wild-type” enzyme means an enzyme expressed by a naturally occurring microorganism, such as a bacterium, yeast, or filamentous fungus found in nature.

Allelic Variant:

[0035]The term “allelic variant” means any of two or more (e.g., several) alternative forms of a gene occupying the same chromosomal locus. Allelic variation arises naturally through mutation, and may result in polymorphism within populations. Gene mutations can be silent (no change in the encoded polypeptide) or may encode polypeptides having altered amino acid sequences. An allelic variant of a polypeptide is a polypeptide encoded by an allelic variant of a gene.

Coding Sequence:

[0036]The term “coding sequence” means a polynucleotide, which directly specifies the amino acid sequence of a polypeptide. The boundaries of the coding sequence are generally determined by an open reading frame, which begins with a start codon such as ATG, GTG, or TTG and ends with a stop codon such as TAA, TAG, or TGA. The coding sequence may be a genomic DNA, cDNA, synthetic DNA, or a combination thereof.

Fragment:

[0037]The term “fragment” means a polypeptide having one or more (e.g., several) amino acids absent from the amino and/or carboxyl terminus of a mature polypeptide main; wherein the fragment has enzyme activity. In one aspect, a fragment contains at least 85%, e.g., at least 90% or at least 95% of the amino acid residues of the mature polypeptide of an enzyme.

Mature Polypeptide:

[0038]The term “mature polypeptide” means a polypeptide in its final form following translation and any post-translational modifications, such as N-terminal processing, C-terminal truncation, glycosylation, phosphorylation, etc. For instance, the mature polypeptide of an A. fumigatus cellobiohydrolase I is amino acids 27 to 532 of SEQ ID NO: 10 herein based on the SignalP program (Nielsen et al., 1997, Protein Engineering 10: 1-6) that predicts amino acids 1 to 26 of SEQ ID NO: 10 herein are a signal peptide. In another aspect, the mature polypeptide of an A. fumigates cellobiohydrolase II is amino acids 20 to 454 of SEQ ID NO: 11 herein based on the SignalP program that predicts amino acids 1 to 19 of SEQ ID NO: 11 herein are a signal peptide. In another aspect, the mature polypeptide of an A. fumigatus beta-glucosidase is amino acids 20 to 863 of SEQ ID NO: 5 herein based on the SignalP program that predicts amino acids 1 to 19 of SEQ ID NO: 5 herein are a signal peptide. In another aspect, the mature polypeptide of a Penicillium sp. GH61 polypeptide is amino acids 26 to 253 of SEQ ID NO: 7 herein based on the SignalP program that predicts amino acids 1 to 25 of SEQ ID NO: 7 herein are a signal peptide.

[0000]It is known in the art that a host cell may produce a mixture of two of more different mature polypeptides (i.e., with a different C-terminal and/or N-terminal amino acid) expressed by the same polynucleotide.

Mature Polypeptide Coding Sequence:

[0039]The term “mature polypeptide coding sequence” means a polynucleotide that encodes a mature polypeptide having enzyme activity.

Parent Enzyme:

[0040]The term “parent” means an enzyme to which an alteration is made to produce a variant. The parent may be a naturally occurring (wild-type) polypeptide or a variant thereof.

Pretreated Corn Stover:

[0041]The term “PCS” or “Pretreated Corn Stover” means a cellulosic material derived from corn stover by treatment with heat and dilute sulfuric acid, alkaline pretreatment, or neutral pretreatment.

Sequence Identity:

[0042]The relatedness between two amino acid sequences or between two nucleotide sequences is described by the parameter “sequence identity”.

[0000]For purposes of the present invention, the sequence identity between two amino acid sequences is determined using the Needleman-Wunsch algorithm (Needleman and Wunsch, 1970, J. Mol. Biol. 48: 443-453) as implemented in the Needle program of the EMBOSS package (EMBOSS: The European Molecular Biology Open Software Suite, Rice et al., 2000, Trends Genet. 16: 276-277), preferably version 5.0.0 or later. The parameters used are gap open penalty of 10, gap extension penalty of 0.5, and the EBLOSUM62 (EMBOSS version of BLOSUM62) substitution matrix. The output of Needle labeled “longest identity” (obtained using the −nobrief option) is used as the percent identity and is calculated as follows:

[0000]

(Identical Residues×100)/(Length of Alignment−Total Number of Gaps in Alignment)

[0000]For purposes of the present invention, the sequence identity between two deoxyribonucleotide sequences is determined using the Needleman-Wunsch algorithm (Needleman and Wunsch, 1970, supra) as implemented in the Needle program of the EMBOSS package (EMBOSS: The European Molecular Biology Open Software Suite, Rice et al., 2000, supra), preferably version 5.0.0 or later. The parameters used are gap open penalty of 10, gap extension penalty of 0.5, and the EDNAFULL (EMBOSS version of NCBI NUC4.4) substitution matrix. The output of Needle labeled “longest identity” (obtained using the −nobrief option) is used as the percent identity and is calculated as follows:

[0000]

(Identical Deoxyribonucleotides×100)/(Length of Alignment−Total Number of Gaps in Alignment)

Subsequence:

[0043]The term “subsequence” means a polynucleotide having one or more (e.g., several) nucleotides absent from the 5′ and/or 3′ end of a mature polypeptide coding sequence; wherein the subsequence encodes a fragment having enzyme activity. In one aspect, a subsequence contains at least 85%, e.g., at least 90% or at least 95% of the nucleotides of the mature polypeptide coding sequence of an enzyme.

[0044]Reference to “about” a value or parameter herein includes aspects that are directed to that value or parameter per se. For example, description referring to “about X” includes the aspect “X”.

[0045]As used herein and in the appended claims, the singular forms “a,” “or,” and “the” include plural referents unless the context clearly dictates otherwise. It is understood that the aspects of the invention described herein include “consisting” and/or “consisting essentially of” aspects.

[0046]Unless defined otherwise or clearly indicated by context, all technical and scientific terms used herein have the same meaning as commonly understood by one of ordinary skill in the art to which this invention belongs.

BRIEF DESCRIPTION OF THE DRAWINGS

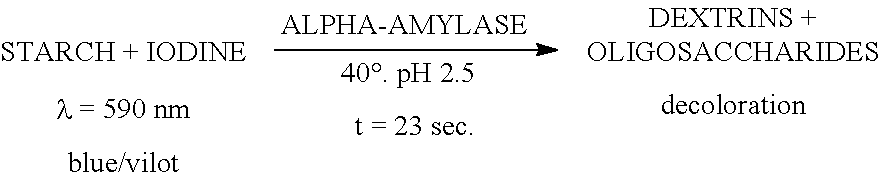

[0047]FIG. 1 is a graph of glucose concentration after hydrolysis of preconditioned uwPCF under the conditions described in Example 1.

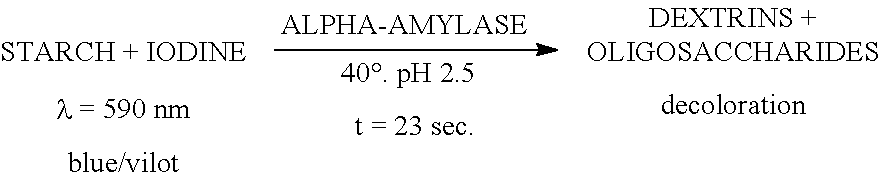

[0048]FIG. 2 is a graph of glucose concentration in response to varied laccase doses on low solids uwPCF under the conditions described in Example 5.

DETAILED DESCRIPTION

[0049]Described herein are processes for preconditioning biomass to increase production of fermentable sugars and to decrease production of interfering byproducts, such as oligomers (e.g., DP2) and lignin-based inhibitors. Also described are preconditioning compositions suitable for use in the processes and/or methods described herein. Further described are processes of producing hydrolysis products using such preconditioned biomass and to processes of producing fermentation products using such preconditioned biomass.

[0050]The present inventors have surprisingly found that enzymatic preconditioning of lignocellulose-containing material with a combination of laccase and beta-glucosidase before saccharifying (i.e., hydrolyzing) with a cellulolytic enzyme preparation results in decreased inhibitors of saccharification and lignin based inhibitors. The preconditioning therefore results in improved saccharification, e.g. improved sugar concentrations, as compared to when no preconditioning is done.

[0051]In a particular embodiment the preconditioning is carried out before saccharification (i.e., hydrolysis), in which sugars are produced.

[0052]Methods of the invention result in increased yield of fermentable sugars and, ultimately, fermentation products, as compared to preconditioning with laccase without beta-glucosidase. The laccase mode of action is known to be through the creation of semi-stable free radicals. While not wishing to be bound by any particular theory, it is believed that a combination of laccase and beta-glucosidase work synergistically to create more accessible cellulose for subsequent hydrolysis. Because the free radicals can degrade proteins/enzymes, in a particular embodiment the methods described herein are provided as a preconditioning step, prior to hydrolysis.

[0053]Subsequently, the sugars may be converted into a number of products including fermentation products (e.g., ethanol or butanol) or into syrups (e.g., High Fructose Corn Syrup (HFCS) and lignocellulose-derived plastics including polyethylene, polystyrene, polypropylene). Other end products include lactic acid which can serve as a feedstock for production of polylactic acid (PLA) to replace petrochemical packaging materials such as PET.

Cellulosic Material

[0054]The processes of the present invention are carried out using cellulosic material. The term “cellulosic material” means any material containing cellulose. The predominant polysaccharide in the primary cell wall of biomass is cellulose, the second most abundant is hemicellulose, and the third is pectin. The secondary cell wall, produced after the cell has stopped growing, also contains polysaccharides and is strengthened by polymeric lignin covalently cross-linked to hemicellulose. Cellulose is a homopolymer of anhydrocellobiose and thus a linear beta-(1-4)-D-glucan, while hemicelluloses include a variety of compounds, such as xylans, xyloglucans, arabinoxylans, and mannans in complex branched structures with a spectrum of substituents. Although generally polymorphous, cellulose is found in plant tissue primarily as an insoluble crystalline matrix of parallel glucan chains. Hemicelluloses usually hydrogen bond to cellulose, as well as to other hemicelluloses, which help stabilize the cell wall matrix.

[0055]Cellulose is generally found, for example, in the stems, leaves, hulls, husks, and cobs of plants or leaves, branches, and wood of trees. The cellulosic material may be, but is not limited to, agricultural residue, herbaceous material (including energy crops), municipal solid waste, pulp and paper mill residue, waste paper, and wood (including forestry residue) (see, for example, Wiselogel et al., 1995, in Handbook on Bioethanol (Charles E. Wyman, editor), pp. 105-118, Taylor & Francis, Washington D.C.; Wyman, 1994, Bioresource Technology 50: 3-16; Lynd, 1990, Applied Biochemistry and Biotechnology 24/25: 695-719; Mosier et al., 1999, Recent Progress in Bioconversion of Lignocellulosics, in Advances in Biochemical Engineering/Biotechnology, T. Scheper, managing editor, Volume 65, pp. 23-40, Springer-Verlag, New York). It is understood herein that the cellulose may be in the form of lignocellulose, a plant cell wall material containing lignin, cellulose, and hemicellulose in a mixed matrix. In a preferred embodiment, the cellulosic material is any biomass material. In another preferred embodiment, the cellulosic material is lignocellulose, which comprises cellulose, hemicelluloses, and lignin.

[0056]In an embodiment, the cellulosic material is agricultural residue, herbaceous material (including energy crops), municipal solid waste, pulp and paper mill residue, waste paper, or wood (including forestry residue).

[0057]In another embodiment, the cellulosic material is arundo, bagasse, bamboo, corn cob, corn fiber, corn stover, miscanthus, rice straw, switchgrass, or wheat straw.

[0058]Corn kernels are comprised of three main components: bran, endosperm, and germ. Corn bran holds the fiber, the hard outer layer of the kernel. The endosperm contains the majority of the starch, found on the interior of the kernel. The germ is at the center of the kernel by the bottom tip cap, containing an abundance of proteins and oils.

[0059]In one embodiment, the cellulosic material is fiber, such as corn fiber or wheat fiber. Fiber, such as corn or wheat fiber, may be obtained by fractionation. Fractionation technologies are well-known in the art. In one embodiment the cellulosic material is fiber obtained from dry fractionation processes. In one embodiment the cellulosic material is fiber obtained from wet fractionation processes.

[0060]In another embodiment, the cellulosic material is aspen, eucalyptus, fir, pine, poplar, spruce, or willow.

[0061]In another embodiment, the cellulosic material is algal cellulose, bacterial cellulose, cotton linter, filter paper, microcrystalline cellulose (e.g., AVICEL®), or phosphoric-acid treated cellulose.

[0062]In another embodiment, the cellulosic material is an aquatic biomass. As used herein the term “aquatic biomass” means biomass produced in an aquatic environment by a photosynthesis process. The aquatic biomass may be algae, emergent plants, floating-leaf plants, or submerged plants.

[0063]The cellulosic material may be used as is or may be subjected to pretreatment, using conventional methods known in the art, as described more fully herein. In a preferred embodiment, the cellulosic material is pretreated.

Pretreatment of Cellulosic Material

[0064]In practicing the processes of the present invention, any pretreatment process known in the art may be used to disrupt plant cell wall components of the cellulosic material (Chandra et al., 2007, Adv. Biochem. Engin./Biotechnol. 108: 67-93; Galbe and Zacchi, 2007, Adv. Biochem. Engin./Biotechnol. 108: 41-65; Hendriks and Zeeman, 2009, Bioresource Technology 100: 10-18; Mosier et al., 2005, Bioresource Technology 96: 673-686; Taherzadeh and Karimi, 2008, Int. J. Mol. Sci. 9: 1621-1651; Yang and Wyman, 2008, Biofuels Bioproducts and Biorefining-Biofpr. 2: 26-40).

[0065]The cellulosic material may also be subjected to particle size reduction, sieving, pre-soaking, wetting, washing, and/or conditioning prior to or with additional pretreatment methods, using methods known in the art or as otherwise described herein.

[0066]Conventional pretreatments include, but are not limited to, steam pretreatment (with or without explosion), dilute acid pretreatment, hot water pretreatment, alkaline pretreatment, lime pretreatment, wet oxidation, wet explosion, ammonia fiber explosion, organosolv pretreatment, and biological pretreatment. Additional pretreatments include ammonia percolation, ultrasound, electroporation, microwave, supercritical CO2, supercritical H2O, ozone, ionic liquid, and gamma irradiation pretreatments.

[0067]In an embodiment the cellulosic material is pretreated before hydrolysis and/or fermentation. Pretreatment is preferably performed prior to the hydrolysis. In a further embodiment preconditioning is performed after pretreatment and before hydrolysis and fermentation.

[0068]Alternatively, pretreatment may be carried out simultaneously with enzyme hydrolysis to release fermentable sugars, such as glucose, xylose, and/or cellobiose. In most cases the pretreatment step itself results in some conversion of biomass to fermentable sugars (even in absence of enzymes).

[0069]Steam Pretreatment. In steam pretreatment, the cellulosic material is heated to disrupt the plant cell wall components, including lignin, hemicellulose, and cellulose to make the cellulose and other fractions, e.g., hemicellulose, accessible to enzymes. The cellulosic material is passed to or through a reaction vessel where steam is injected to increase the temperature to the required temperature and pressure and is retained therein for the desired reaction time. Steam pretreatment is preferably performed at 140-250° C., e.g., 160-200° C. or 170-190° C., where the optimal temperature range depends on optional addition of a chemical catalyst. Residence time for the steam pretreatment is preferably 1-60 minutes, e.g., 1-30 minutes, 1-20 minutes, 3-12 minutes, or 4-10 minutes, where the optimal residence time depends on the temperature and optional addition of a chemical catalyst. Steam pretreatment allows for relatively high solids loadings, so that the cellulosic material is generally only moist during the pretreatment. The steam pretreatment is often combined with an explosive discharge of the material after the pretreatment, which is known as steam explosion, that is, rapid flashing to atmospheric pressure and turbulent flow of the material to increase the accessible surface area by fragmentation (Duff and Murray, 1996, Bioresource Technology 855: 1-33; Galbe and Zacchi, 2002, Appl. Microbiol. Biotechnol. 59: 618-628; U.S. Patent Application No. 2002/0164730). During steam pretreatment, hemicellulose acetyl groups are cleaved and the resulting acid autocatalyzes partial hydrolysis of the hemicellulose to monosaccharides and oligosaccharides. Lignin is removed to only a limited extent.

[0070]Chemical Pretreatment: The term “chemical pretreatment” refers to any chemical pretreatment that promotes the separation and/or release of cellulose, hemicellulose, and/or lignin. Such a pretreatment may convert crystalline cellulose to amorphous cellulose. Examples of suitable chemical pretreatment processes include, for example, dilute acid pretreatment, lime pretreatment, wet oxidation, ammonia fiber/freeze expansion (AFEX), ammonia percolation (APR), ionic liquid, and organosolv pretreatments.

[0071]A chemical catalyst such as H2SO4 or SO2 (typically 0.3 to 5% w/w) is sometimes added prior to steam pretreatment, which decreases the time and temperature, increases the recovery, and improves enzymatic hydrolysis (Ballesteros et al., 2006, Appl. Biochem. Biotechnol. 129-132: 496-508; Varga et al., 2004, Appl. Biochem. Biotechnol. 113-116: 509-523; Sassner et al., 2006, Enzyme Microb. Technol. 39: 756-762). In dilute acid pretreatment, the cellulosic material is mixed with dilute acid, typically H2SO4, and water to form a slurry, heated by steam to the desired temperature, and after a residence time flashed to atmospheric pressure. The dilute acid pretreatment may be performed with a number of reactor designs, e.g., plug-flow reactors, counter-current reactors, or continuous counter-current shrinking bed reactors (Duff and Murray, 1996, supra; Schell et al., 2004, Bioresource Technology 91: 179-188; Lee et al., 1999, Adv. Biochem. Eng. Biotechnol. 65: 93-115).

[0072]Several methods of pretreatment under alkaline conditions may also be used. These alkaline pretreatments include, but are not limited to, sodium hydroxide, lime, wet oxidation, ammonia percolation (APR), and ammonia fiber/freeze expansion (AFEX) pretreatment.

[0073]Lime pretreatment is performed with calcium oxide or calcium hydroxide at temperatures of 85-150° C. and residence times from 1 hour to several days (Wyman et al., 2005, Bioresource Technology 96: 1959-1966; Mosier et al., 2005, supra). WO 2006/110891, WO 2006/110899, WO 2006/110900, and WO 2006/110901 disclose pretreatment methods using ammonia.

[0074]Wet oxidation is a thermal pretreatment performed typically at 180-200° C. for 5-15 minutes with addition of an oxidative agent such as hydrogen peroxide or over-pressure of oxygen (Schmidt and Thomsen, 1998, Bioresource Technology 64: 139-151; Palonen et al., 2004, Appl. Biochem. Biotechnol. 117: 1-17; Varga et al., 2004, Biotechnol. Bioeng. 88: 567-574; Martin et al., 2006, J. Chem. Technol. Biotechnol. 81: 1669-1677). The pretreatment is performed preferably at 1-40% dry matter, e.g., 2-30% dry matter or 5-20% dry matter, and often the initial pH is increased by the addition of alkali such as sodium carbonate.

[0075]A modification of the wet oxidation pretreatment method, known as wet explosion (combination of wet oxidation and steam explosion) can handle dry matter up to 30%. In wet explosion, the oxidizing agent is introduced during pretreatment after a certain residence time. The pretreatment is then ended by flashing to atmospheric pressure (WO 2006/032282).

[0076]Ammonia fiber expansion (AFEX) involves treating the cellulosic material with liquid or gaseous ammonia at moderate temperatures such as 90-150° C. and high pressure such as 17-20 bar for 5-10 minutes, where the dry matter content can be as high as 60% (Gollapalli et al., 2002, Appl. Biochem. Biotechnol. 98: 23-35; Chundawat et al., 2007, Biotechnol. Bioeng. 96: 219-231; Alizadeh et al., 2005, Appl. Biochem. Biotechnol. 121: 1133-1141; Teymouri et al., 2005, Bioresource Technology 96: 2014-2018). During AFEX pretreatment cellulose and hemicelluloses remain relatively intact. Lignin-carbohydrate complexes are cleaved.

[0077]Organosolv pretreatment delignifies the cellulosic material by extraction using aqueous ethanol (40-60% ethanol) at 160-200° C. for 30-60 minutes (Pan et al., 2005, Biotechnol. Bioeng. 90: 473-481; Pan et al., 2006, Biotechnol. Bioeng. 94: 851-861; Kurabi et al., 2005, Appl. Biochem. Biotechnol. 121: 219-230). Sulphuric acid is usually added as a catalyst. In organosolv pretreatment, the majority of hemicellulose and lignin is removed.

[0078]Other examples of suitable pretreatment methods are described by Schell et al., 2003, Appl. Biochem. Biotechnol. 105-108: 69-85, and Mosier et al., 2005, supra, and U.S. Published Application 2002/0164730.

[0079]In one embodiment, the chemical pretreatment is preferably carried out as a dilute acid treatment, and more preferably as a continuous dilute acid treatment. The acid is typically sulfuric acid, but other acids may also be used, such as acetic acid, citric acid, nitric acid, phosphoric acid, tartaric acid, succinic acid, hydrogen chloride, or mixtures thereof. Mild acid treatment is conducted in the pH range of preferably 1-5, e.g., 1-4 or 1-2.5. In one embodiment, the acid concentration is in the range from preferably 0.01 to 10 wt. % acid, e.g., 0.05 to 5 wt. % acid or 0.1 to 2 wt. % acid. The acid is contacted with the cellulosic material and held at a temperature in the range of preferably 140-200° C., e.g., 165-190° C., for periods ranging from 1 to 60 minutes.

[0080]In another embodiment, pretreatment takes place in an aqueous slurry. In preferred embodiments, the cellulosic material is present during pretreatment in amounts preferably between 10-80 wt. %, e.g., 20-70 wt. % or 30-60 wt. %, such as around 40 wt. %. The pretreated cellulosic material may be unwashed or washed using any method known in the art, e.g., washed with water.

[0081]Mechanical Pretreatment or Physical Pretreatment: The term “mechanical pretreatment” or “physical pretreatment” refers to any pretreatment that promotes size reduction of particles. For example, such pretreatment may involve various types of grinding or milling (e.g., dry milling, wet milling, or vibratory ball milling).

[0082]The cellulosic material may be pretreated both physically (mechanically) and chemically. Mechanical or physical pretreatment may be coupled with steaming/steam explosion, hydrothermolysis, dilute or mild acid treatment, high temperature, high pressure treatment, irradiation (e.g., microwave irradiation), or combinations thereof. In one embodiment, high pressure means pressure in the range of preferably about 100 to about 400 psi, e.g., about 150 to about 250 psi. In another embodiment, high temperature means temperature in the range of about 100 to about 300° C., e.g., about 140 to about 200° C. In a preferred embodiment, mechanical or physical pretreatment is performed in a batch-process using a steam gun hydrolyzer system that uses high pressure and high temperature as defined above, e.g., a Sunds Hydrolyzer available from Sunds Defibrator AB, Sweden. The physical and chemical pretreatments may be carried out sequentially or simultaneously, as desired.

[0083]Accordingly, in a preferred embodiment, the cellulosic material is subjected to physical (mechanical) or chemical pretreatment, or any combination thereof, to promote the separation and/or release of cellulose, hemicellulose, and/or lignin.

[0084]Biological Pretreatment: The term “biological pretreatment” refers to any biological pretreatment that promotes the separation and/or release of cellulose, hemicellulose, and/or lignin from the cellulosic material. Biological pretreatment techniques may involve applying lignin-solubilizing microorganisms and/or enzymes (see, for example, Hsu, T.-A., 1996, Pretreatment of biomass, in Handbook on Bioethanol: Production and Utilization, Wyman, C. E., ed., Taylor & Francis, Washington, D.C., 179-212; Ghosh and Singh, 1993, Adv. Appl. Microbiol. 39: 295-333; McMillan, J. D., 1994, Pretreating lignocellulosic biomass: a review, in Enzymatic Conversion of Biomass for Fuels Production, Himmel, M. E., Baker, J. O., and Overend, R. P., eds., ACS Symposium Series 566, American Chemical Society, Washington, D.C., chapter 15; Gong, C. S., Cao, N. J., Du, J., and Tsao, G. T., 1999, Ethanol production from renewable resources, in Advances in Biochemical Engineering/Biotechnology, Scheper, T., ed., Springer-Verlag Berlin Heidelberg, Germany, 65: 207-241; Olsson and Hahn-Hagerdal, 1996, Enz. Microb. Tech. 18: 312-331; and Vallander and Eriksson, 1990, Adv. Biochem. Eng./Biotechnol. 42: 63-95).

Processes for Preconditioning Pretreated Cellulosic Material

[0085]When lignocellulose-containing material is pretreated, degradation products that may be inhibitory to enzymes or toxic to fermenting organisms may be produced. These degradation products severely decrease both hydrolysis and fermentation processes and therefore reduction of the degradation products is desired.

[0086]The inventors have found that preconditioning pretreated lignocellulose-containing material with a combination of a phenol oxidizing enzyme and a glycosidase is effective to reduce degradation products from pretreatment of lignocellulose-containing material. In an embodiment, the combination of phenol oxidizing enzyme and glycosidase comprises laccase and beta-glucosidase.

[0087]As used herein “preconditioning” refers to conditioning of a cellulosic material. In a particular embodiment the preconditioning is performed after cellulosic material has been pretreated. In another embodiment the preconditioning is performed before the cellulosic material has been hydrolyzed (saccharified). “Preconditioning” may also be referred to as detoxification of pretreated cellulosic material or to a stage of pretreatment within a multi-stage pretreatment process, after a step of pretreatment to disrupt plant cell wall components of the cellulosic material has occurred.

[0088]As used herein, “degradation products” include lignin degradation products, cellulose degradation products and hemicellulose degradation products. The pretreated lignin degradation products may be phenolics in nature. The pretreated cellulose degradation products may comprise cellodextrins, e.g., cellobiose, cellotriose, etc.

[0089]Hemicellulose degradation products include furans from sugars (such as hexoses and/or pentoses), including xylose, mannose, galactose, rhamanose, and arabinose. Examples of hemicelluloses include xylan, galactoglucomannan, arabinogalactan, arabinoglucuronoxylan, glucuronoxylan, and derivatives and combinations thereof.

[0090]Examples of inhibitory compounds, i.e., pretreated lignocellulose degradation products, include 4-OH benzyl alcohol, 4-OH benzaldehyde, 4-OH benzoic acid, trimethyl benzaldehyde, 2-furoic acid, coumaric acid, ferulic acid, phenol, guaiacol, veratrole, pyrogallollol, pyrogallol mono methyl ether, vanillyl alcohol, vanillin, isovanillin, vanillic acid, isovanillic acid, homovanillic acid, veratryl alcohol, veratraldehyde, veratric acid, 2-O-methyl gallic acid, syringyl alcohol, syringaldehyde, syringic acid, trimethyl gallic acid, homocatechol, ethyl vanillin, creosol, p-methyl anisol, anisaldehyde, anisic acid, furfural, hydroxymethylfurfural, 5-hydroxymethylfurfural, formic acid, acetic acid, levulinic acid, cinnamic acid, coniferyl aldehyde, isoeugenol, hydroquinone, eugenol or combinations thereof. Other inhibitory compounds may be found in, e.g., Luo et al., 2002, Biomass and Bioenergy 22: 125-138.

[0091]Preconditioning processes described herein are preferably carried out at a pH that is suitable for the phenol oxidizing enzyme and glycosidase. In one embodiment the pH is between 2 and 7, preferably between about 3 and about 6, especially between about 4 and about 5.5, more particularly about 5.0, 5.1, 5.2 or 5.3. In a preferred embodiment the temperature during preconditioning is a temperature suitable for the phenol oxidizing enzyme and a glycosidase. In one embodiment the temperature during preconditioning is between 20° C. and 70° C., preferably between about 40° C. and about 60° C., more preferably about 50° C. In an embodiment preconditioning incubating occurs for at least 30 minutes, e.g., at least about 1 hour, at least about 2 hours, at least about 3 hours, at least about 4 hours, at least about 5 hours, at least about 8 hours, at least about 12 hours, or at least about 24 hours, such as from about 30 minutes to about 24 hours.

[0092]Suitable pHs, temperatures and other process conditions can easily be determined by one skilled in the art.

[0093]By preconditioning processes described herein, hydrolysis can be significantly improved at low hydrolysis enzyme loading, such that a similar sugar concentration can be obtained from less hydrolysis enzymes than would be used in hydrolysis of non-preconditioned material. Correspondingly, use of the same enzyme loading as would be used in hydrolysis of non-preconditioned material in hydrolysis of preconditioned material, would increase production of hydrolysis products.

[0094]Furthermore, by preconditioning processes described herein, fermentation time may be reduced, such that the total time from material to fermentation product is reduced. Additionally, preconditioning processes described herein may reduce the need for a washing step after pretreatment of the lignocellulose-containing material.

[0095]Therefore, in an embodiment, the invention relates to processes for preconditioning pretreated lignocellulose-containing material, the processes comprising incubating pretreated lignocellulose-containing material with a combination of a phenol oxidizing enzyme and a glycosidase. In a particular embodiment the invention relates to processes for preconditioning pretreated lignocellulose-containing material, the processes comprising incubating pretreated lignocellulose-containing material with laccase and beta-glucosidase.

[0096]In an embodiment, the preconditioning enzymes may be added in preconditioning processes simultaneously or separately. In one embodiment the laccase and the beta-glucosidase are added at or about the same time. In another embodiment the laccase is added prior to addition of the beta-glucosidase. In yet another embodiment the beta-glucosidase is added prior to addition of the laccase.

[0097]The processes of preconditioning are preferably conducted prior to saccharification of the cellulosic material. In an embodiment the invention relates to processes for preconditioning pretreated lignocellulose-containing material, the processes comprising incubating pretreated lignocellulose-containing material with laccase and beta-glucosidase, prior to saccharification of the pretreated lignocellulose-containing material. As demonstrated in the examples, enzymatic preconditioning of dilute acid pretreated fractionated unwashed corn fiber with a combination of laccase and beta-glucosidase before saccharifying (i.e., hydrolyzing) with a cellulolytic enzyme preparation resulted in increased glucose concentrations (See Example 1, Kettles R4 and R5), as compared to no preconditioning being done (See Example 1, Kettle R1), preconditioning with laccase alone (See Example 1, Kettle R2, R6), and preconditioning with laccase and a small amount of a cellulolytic enzyme preparation or hemicellulolytic enzyme preparation (See Example 1, Kettles R3, R7 and R8).

[0098]Example 5 demonstrates that in an enzymatic preconditioning screening trial, dose responses of laccase (liquid and granular) were evaluated on low solids unwashed pretreated corn stover. Because of the high starch content of dry fractionated corn fiber, a low dose of cellulolytic enzyme preparation may be realized. Additionally evaluated was a blend of glucoamylase to show the benefit of addition of a cellulolytic enzyme preparation.

[0099]Therefore in an embodiment the invention relates to processes for preconditioning pretreated lignocellulose-containing material, the processes comprising incubating pretreated lignocellulose-containing material with laccase and beta-glucosidase or a beta-glucosidase containing enzyme preparation for a period of time sufficient to precondition the pretreated lignocellulose-containing material such that the hydrolysis of the preconditioned pretreated lignocellulose-containing material results in an increased yield compared to a pretreated lignocellulose-containing material that is not so preconditioned.

[0100]The lignocellulose-containing material used in processes of the invention may be pretreated. The pretreated lignocellulose-containing material may be pretreated using any suitable method. Suitable pretreatment methods are known in the art, such as those listed in the “Pretreatment”-section herein. In a preferred embodiment the pretreated lignocellulose-containing material has been dilute acid pretreated or auto-hydrolyzed before preconditioning. In one embodiment the lignocellulose-containing material may be pretreated corn fiber, pretreated corn stover (PCS), pretreated corn cob, pretreated wheat straw, pretreated rice straw or pretreated switch grass. In a preferred embodiment the lignocellulose-containing material is dilute acid pretreated corn fiber. Other examples of contemplated material are described in the “Cellulosic Materials”-section herein.

[0101]In another embodiment the pretreated lignocellulose-containing material is unwashed. In an embodiment the pretreated lignocellulose-containing material is un-detoxified. In an embodiment the lignocellulose-containing material is washed, undetoxified or unwashed pretreated corn fiber, corn stover (PCS), corn cob, wheat straw, rice straw and/or switch grass. In an embodiment the lignocellulose-containing material is fractionated. In an embodiment the lignocellulose-containing material may be pretreated dry fractionated corn fiber. In another embodiment the lignocellulose-containing material may be pretreated dry fractionated unwashed corn fiber. In an embodiment the lignocellulose-containing material may be pretreated wet fractionated corn fiber. In an embodiment preconditioning occurs at about 5-50% TS (Total Solids), such as about 10-40% TS, such as about 15-35% TS.

Preconditioning Enzymes

[0102]The preconditioning enzymes may be of any origin, including of mammalian, plant and microbial origin, such as bacterial and fungal origin.

[0103]Phenol oxidizing enzymes may in preferred embodiments belong to any of the following EC classes including: Catechol oxidase (EC 1.10.3.1), Laccase (EC 1.10.3.2), o-Aminophenol oxidase (1.10.3.4); and Monophenol monooxygenase (1.14.18.1).

[0104]In one embodiment, processes of the invention comprise addition of laccase as a preconditioning enzyme. The laccase may belong to the following EC class: Laccase (EC 1.10.3.2). In a preferred embodiment the laccase is a laccase such as one from Myceliophthora thermophila (MtL), such as the laccase set forth as SEQ ID NO: 2 in WO 95/33836 (SEQ ID NO: 1 herein). In an embodiment the laccase has at least 60%, at least 70% at least 80%, at least 85%, at least 90%, at least 95%, at least 97%, at least 98%, at least 99% sequence identity to the Myceliophthora thermophila laccase disclosed as SEQ ID NO: 2 in WO 95/33836 (SEQ ID NO: 1 herein). Other suitable laccases are mentioned in the “Laccases”-section below. In an embodiment the laccase loading is between 1-500 μg, such as 5-100 μg EP/g cellulose. In an embodiment the laccase loading is between 0.005 and 20 mg Enzyme Protein (EP)/g cellulose, such as 0.1-1 mg EP/g cellulose. In various embodiments the laccase is in liquid form, granular form or powdered form.

[0105]The glycosidase may in preferred embodiments belong to any of the following EC classes including: glucosidases (E.C. 3.2.1), beta-glucosidase (E.C.3.2.1.21), glucoamylase (E.C. 3.2.1.3) and alpha-glucosidase (E.C. 3.2.1.20).

[0106]In an embodiment, processes of the invention comprise addition of beta-glucosidase as a preconditioning enzyme. The beta-glucosidase may be derived from a strain of Aspergillus, such as Aspergillus niger, Aspergillus fumigatus, or Aspergillus oryzae. In an embodiment the beta-glucosidase loading is between 0.01 and 20 mg EP/g cellulose, such as 0.1-1 mg EP/g cellulose. In an embodiment the beta-glucosidase is comprised in a beta-glucosidase containing enzyme preparation. Other suitable beta-glucosidases and beta-glucosidase containing enzyme preparations are mentioned in the “beta-glucosidase”-section below.

[0107]In various embodiments, additional enzymes may be present or included during preconditioning processes, including, but not limited to, cellulases and hemicellulases.

[0108]In embodiments of processes of the invention, preconditioning enzymes may be added separately or simultaneously.

[0109]In a further embodiment the invention provides preconditioning compositions comprising one or more preconditioning enzymes as described herein. In one embodiment the invention provides enzyme preconditioning compositions comprising laccase and/or beta-glucosidase.

[0110]Additional information regarding preconditioning enzymes contemplated according to methods of the invention and examples thereof may be found in the “Enzymes” section below.

[0000]Producing Hydrolysis Products from Preconditioned Pretreated Cellulosic Material

[0111]In another embodiment, the invention relates to processes for producing a hydrolysis product from pretreated lignocellulose-containing material, comprising:

- (i) preconditioning a pretreated lignocellulose-containing material; and

- (ii) hydrolyzing the preconditioned pretreated lignocellulose-containing material with a cellulolytic enzyme composition, to obtain a hydrolysis product.

[0114]Suitable lignocellulose-containing material and methods or processes of pretreating and preconditioning such materials according to embodiments of the invention are described more fully herein. In one embodiment the preconditioning comprises incubating the pretreated lignocellulose-containing material with a combination of a phenol oxidizing enzyme and a glycosidase. In a particular embodiment the phenol oxidizing enzyme is a laccase, such as one from Myceliophthora thermophila (MtL) (WO 95/33836 (SEQ ID NO: 1 herein)) and the glycosidase is a beta-glucosidase or a beta-glucosidase containing enzyme preparation. In an embodiment, preconditioning step (i) is carried out in accordance with preconditioning processes described herein.

[0115]In various embodiments of the invention the preconditioning step (i) and hydrolyzing step (ii) are carried out simultaneously or sequentially.

[0116]In simultaneous performance of steps (i) and (ii), the enzymes of each step are added at the same time, or are added in a stepwise fashion, such that the preconditioning step (i) is still occurring, at least in part, at the time of addition of the cellulolytic enzyme composition in hydrolyzing step (ii). As such, at least a portion of each of the preconditioning and hydrolyzing are performed at the same time. In a particular embodiment a time-course evaluation of the conversion of the starting substrate to fermentable sugars is made and timing of the addition of the one or more preconditioning enzymes and the cellulolytic enzyme composition is determined in order to maximize conversion of the substrate to fermentable sugars and maximize the yield of such fermentable sugars.

[0117]In sequential processes, the preconditioning step (i) is completed prior to the initiation of the hydrolyzing step (ii). Completion of the preconditioning step may be determined by depletion of the preconditioning enzyme, use of a predetermined amount of preconditioning enzyme, preconditioning of all substrate, and/or preconditioning of a predetermined amount of substrate.

[0118]In an embodiment where the preconditioning step (i) of sequential processes contains enzymes with activity in the conversion of cellulosic material to fermentable sugars, e.g., cellulases and hemicellulases, such enzymes are present such that only a small portion of the material is converted and that all, or essentially all of the material remains unconverted until the hydrolysis step (ii) is performed. Further, in an embodiment where the preconditioning step (i) of sequential processes contains enzymes with activity in the conversion of cellulosic material to fermentable sugars, e.g., cellulases and hemicellulases, such enzymes are present in an amount sufficient to provide a synergistic effect with regard to generation of free radicals from lignin derivatives and to create more accessible cellulose as compared to a preconditioning step without addition of such enzymes.

Hydrolysis (Saccharification)

[0119]In the hydrolysis step (i.e., saccharification step) the pretreated preconditioned lignocellulose-containing material is hydrolyzed to break down cellulose and/or hemicellulose to fermentable sugars, such as glucose, cellobiose, xylose, xylulose, arabinose, mannose, galactose, and/or soluble oligosaccharides. The saccharification is performed enzymatically using a cellulolytic enzyme preparation.

[0120]Enzymatic hydrolysis (i.e., saccharification) may be carried out in a suitable aqueous environment under conditions that may be readily determined by one skilled in the art. In one embodiment, hydrolysis is performed under conditions suitable for the activity of the cellulolytic enzyme preparation, preferably optimal for the cellulolytic enzyme preparation. The hydrolysis may be carried out as a fed batch or continuous process where the preconditioned unwashed pretreated lignocellulose-containing material (substrate) is fed gradually to, for example, an enzyme containing hydrolysis solution.

[0121]The hydrolysis is generally performed in stirred-tank reactors or fermentors under controlled pH, temperature, and mixing conditions. Suitable process time, temperature and pH conditions may readily be determined by one skilled in the art. For example, the hydrolysis may last up to 200 hours, but is typically performed for preferably about 12 to about 120 hours, e.g., about 16 to about 72 hours or about 24 to about 48 hours. The temperature is in the range of preferably about 25° C. to about 70° C., e.g., about 30° C. to about 65° C., about 40° C. to about 60° C., or about 50° C. to about 55° C. The pH is in the range of preferably about 3 to about 8, e.g., about 3.5 to about 7, about 4 to about 6, or about 4.5 to about 5.5. The dry solids content is in the range of preferably about 5 to about 50 wt. %, e.g., about 10 to about 40 wt. % or about 20 to about 30 wt. %.

[0122]The enzymes used in hydrolysis may comprise any protein useful in degrading the cellulosic material.

[0123]In an embodiment, sugars obtained from hydrolysis step (ii), i.e., a “hydrolysis product,” may be fermented.

[0124]In an embodiment, hydrolysis is carried out in the presence of one or more (e.g., several) proteins selected from the group consisting of a cellulase, an AA9 polypeptide, a hemicellulase, an esterase, an expansin, laccase, a ligninolytic enzyme, an oxidoreductase, a pectinase, a protease, and a swollenin. In another embodiment, the cellulase is preferably one or more (e.g., several) enzymes selected from the group consisting of an endoglucanase, a cellobiohydrolase, and a beta-glucosidase. In another embodiment, the hemicellulase is preferably one or more (e.g., several) enzymes selected from the group consisting of an acetylmannan esterase, an acetylxylan esterase, an arabinanase, an arabinofuranosidase, a coumaric acid esterase, a feruloyl esterase, a galactosidase, a glucuronidase, a glucuronoyl esterase, a mannanase, a mannosidase, a xylanase, and a xylosidase. In another embodiment, the oxidoreductase is preferably one or more (e.g., several) enzymes selected from the group consisting of a catalase, a laccase, and a peroxidase. The compositions may also comprise one or more (e.g., several) enzymes selected from the group consisting of a hydrolase, an isomerase, a ligase, a lyase, an oxidoreductase, or a transferase, e.g., an alpha-galactosidase, alpha-glucosidase, aminopeptidase, amylase, beta-galactosidase, beta-glucosidase, beta-xylosidase, carbohydrase, carboxypeptidase, catalase, cellobiohydrolase, cellulase, chitinase, cutinase, cyclodextrin glycosyltransferase, deoxyribonuclease, endoglucanase, esterase, glucoamylase, invertase, laccase, lipase, mannosidase, mutanase, oxidase, pectinolytic enzyme, peroxidase, phytase, polyphenoloxidase, proteolytic enzyme, ribonuclease, transglutaminase, or xylanase.

[0125]In a further embodiment the hydrolysis is performed in the presence of a glucoamylase. The glucoamylase may be derived from Talaromyces (e.g., Talaromyces emersonii), Trametes (e.g., Trametes cingulate) or Rhizopus (e.g., Rhizopus oryzae).

[0126]In an embodiment the cellulolytic enzyme composition used in hydrolysis may be of fungal origin. In a preferred embodiment the cellulolytic enzyme composition is derived from Trichoderma (e.g., Trichoderma reesei). In a preferred embodiment hydrolysis (saccharification) is carried out in the presence of a cellulolytic enzyme preparation including enzyme activities selected from the group of cellulase, endoglucanase, cellobiohydrolase, and beta-glucosidase (e.g., Aspergillus fumigatus or Aspergillus oryzae beta-glucosidase). In a preferred embodiment hydrolysis is carried out using a polypeptide having cellulolytic enhancing activity (e.g., a Thermoascus aurantiacus or Penicillium emersonii cellulolytic enhancing polypeptide).

[0127]In an embodiment the cellulolytic enzyme preparation used for hydrolysis is of fungal origin, such as derived from Trichoderma (e.g., Trichoderma reesei). A hemicellulase may also be present or added during hydrolysis. In an embodiment hydrolysis is carried out in the presence of a cellulolytic enzyme preparation including enzyme activities selected from the group of endoglucanase, cellobiohydrolase, and beta-glucosidase (e.g., Aspergillus fumigatus beta-glucosidase, such as the one shown in WO 2005/047499 or WO 2012/044915 (SEQ ID NO: 2 herein), or Aspergillus oryzae beta-glucosidase). In an embodiment hydrolysis is carried out in the presence of a polypeptide having cellulolytic enhancing activity, such as GH61 polypeptide, e.g., a Thermoascus aurantiacus GH61 polypeptide, such as the one shown in WO 2005/074656 or Penicillium emersonii GH61 polypeptide, such as the one shown in WO 2011/041397 (SEQ ID NO: 3 herein).

[0128]In an embodiment the hemicellulase may be a xylanase (e.g., an Aspergillus aculeatus, such as the one shown in WO 94/021785 or Aspergillus fumigatus xylanase, such as the one shown in WO 2006/078256 (SEQ ID NO: 6 herein)), or a xylosidase (e.g., Aspergillus fumigatus beta-xylosidase, such as the one shown in WO 2011/057140 (SEQ ID NO: 7 herein)).

[0129]In an embodiment, a hemicellulase, such as a hemicelluloytic enzyme preparation, is present or added during hydrolysis (and/or fermentation). In a preferred embodiment the hemicellulolytic enzyme preparation comprises a cellulolytic enzyme preparation from Trichoderma reesei, further comprising Aspergillus fumigatus xylanase (WO 2006/078256, SEQ ID NO: 6 herein) and Aspergillus fumigatus beta-xylosidase (WO 2011/057140, SEQ ID NO: 7 herein).

[0130]In a preferred embodiment, hydrolysis is carried out in the presence of a cellulolytic enzyme preparation derived from Trichoderma (e.g., Trichoderma reesei) including endoglucanase (EG) and cellobiohydrolase (CBH) further comprises a polypeptide having cellulolytic enhancing activity (e.g., a Thermoascus aurantiacus or Penicillium emersonii cellulolytic enhancing polypeptide) and a beta-glucosidase (e.g., Aspergillus fumigatus or Aspergillus oryzae beta-glucosidase).

[0131]In a preferred embodiment the cellulolytic enzyme preparation, present or added during hydrolysis, is a cellulolytic enzyme preparation derived from Trichoderma reesei further comprising AA9 (GH61A) polypeptide having cellulolytic enhancing activity derived from a strain of Penicillium emersonii (SEQ ID NO: 2 in WO 2011/041397, SEQ ID NO: 3 herein), Aspergillus fumigatus beta-glucosidase (SEQ ID NO: 2 in WO 2005/047499, SEQ ID NO: 2 herein) variant F100D, S283G, N456E, F512Y) disclosed in WO 2012/044915; Aspergillus fumigatus Cel7A CBH1 disclosed as SEQ ID NO: 6 in WO2011/057140 (SEQ ID NO: 4 herein) and Aspergillus fumigatus CBH II disclosed as SEQ ID NO: 18 in WO 2011/057140 (SEQ ID NO: 5 herein). Further, the cellulolytic enzyme preparation may further be supplemented with 10% hemicellulolytic enzyme preparation comprising a cellulolytic enzyme preparation from Trichoderma reesei further comprising Aspergillus fumigatus xylanase (WO 2006/078256) (SEQ ID NO: 6 herein) and Aspergillus fumigatus beta-xylosidase (WO 2011/041397) (SEQ ID NO: 7 herein).

[0132]In the processes of the present invention, the enzyme(s) may be added prior to or during hydrolysis, hydrolysis and fermentation, or fermentation.

[0133]One or more (e.g., several) components of the enzyme composition may be native proteins, recombinant proteins, or a combination of native proteins and recombinant proteins. For example, one or more (e.g., several) components may be native proteins of a cell, which is used as a host cell to express recombinantly one or more (e.g., several) other components of the enzyme composition. It is understood herein that the recombinant proteins may be heterologous (e.g., foreign) and/or native to the host cell. One or more (e.g., several) components of the enzyme composition may be produced as monocomponents, which are then combined to form the enzyme composition. The enzyme composition may be a combination of multicomponent and monocomponent protein preparations.

[0134]The enzymes used in the processes of the present invention may be in any form suitable for use, such as, for example, a fermentation broth formulation or a cell composition, a cell lysate with or without cellular debris, a semi-purified or purified enzyme preparation, or a host cell as a source of the enzymes. The enzyme composition may be a dry powder or granulate, a non-dusting granulate, a liquid, a stabilized liquid, or a stabilized protected enzyme. Liquid enzyme preparations may, for instance, be stabilized by adding stabilizers such as a sugar, a sugar alcohol or another polyol, and/or lactic acid or another organic acid according to established processes.

[0135]The optimum amounts of the enzymes and polypeptides depend on several factors including, but not limited to, the mixture of cellulolytic enzymes and/or hemicellulolytic enzymes, the cellulosic material, the concentration of cellulosic material, the pretreatment of the cellulosic material, temperature, time, pH, and inclusion of a fermenting organism (e.g., for Simultaneous Saccharification and Fermentation).

[0136]In one embodiment, an effective amount of cellulolytic or hemicellulolytic enzyme to the cellulosic material is about 0.5 to about 50 mg, e.g., about 0.5 to about 40 mg, about 0.5 to about 25 mg, about 0.75 to about 20 mg, about 0.75 to about 15 mg, about 0.5 to about 10 mg, or about 2.5 to about 10 mg per g of the cellulosic material.

[0137]The polypeptides having cellulolytic enzyme activity or hemicellulolytic enzyme activity as well as other proteins/polypeptides useful in the degradation of the cellulosic material, e.g., AA9 polypeptides, may be derived or obtained from any suitable origin, including, archaeal, bacterial, fungal, yeast, plant, or animal origin. The term “obtained” also means herein that the enzyme may have been produced recombinantly in a host organism employing methods described herein, wherein the recombinantly produced enzyme is either native or foreign to the host organism or has a modified amino acid sequence, e.g., having one or more (e.g., several) amino acids that are deleted, inserted and/or substituted, i.e., a recombinantly produced enzyme that is a mutant and/or a fragment of a native amino acid sequence or an enzyme produced by nucleic acid shuffling processes known in the art. Encompassed within the meaning of a native enzyme are natural variants and within the meaning of a foreign enzyme are variants obtained by, e.g., site-directed mutagenesis or shuffling.

[0138]Each polypeptide may be a bacterial polypeptide. For example, each polypeptide may be a Gram-positive bacterial polypeptide having enzyme activity, or a Gram-negative bacterial polypeptide having enzyme activity.

[0139]Each polypeptide may also be a fungal polypeptide, e.g., a yeast polypeptide or a filamentous fungal polypeptide.

[0140]Chemically modified or protein engineered mutants of polypeptides may also be used.

[0141]One or more (e.g., several) components of the enzyme composition may be a recombinant component, i.e., produced by cloning of a DNA sequence encoding the single component and subsequent cell transformed with the DNA sequence and expressed in a host (see, for example, WO 91/17243 and WO 91/17244). The host may be a heterologous host (enzyme is foreign to host), but the host may under certain conditions also be a homologous host (enzyme is native to host). Monocomponent cellulolytic proteins may also be prepared by purifying such a protein from a fermentation broth.

[0142]In one embodiment, the one or more (e.g., several) cellulolytic enzymes comprise a commercial cellulolytic enzyme preparation. Examples of commercial cellulolytic enzyme preparations suitable for use in the present invention include, for example, CELLIC® CTec (Novozymes A/S), CELLIC® CTec2 (Novozymes A/S), CELLIC® CTec3 (Novozymes A/S), CELLUCLAST® (Novozymes A/S), NOVOZYM® 188 (Novozymes A/S), SPEZYME® CP (Genencor Int.), ACCELLERASE® TRIO (Danisco US Inc.), FILTRASE™ NL (DSM); METHAPLUS® S/L 100 (DSM), ROHAMENT® 7069 W (Röhm GmbH), or ALTERNAFUEL® CMAX3 (Dyadic International, Inc.). The cellulolytic enzyme preparation is added in an amount effective from about 0.001 to about 5.0 wt. % of solids, e.g., about 0.025 to about 4.0 wt. % of solids or about 0.005 to about 2.0 wt. % of solids.

[0143]Examples of bacterial endoglucanases that may be used in the processes of the present invention, include, but are not limited to, Acidothermus cellulolyticus endoglucanase (WO 91/05039; WO 93/15186; U.S. Pat. No. 5,275,944; WO 96/02551; U.S. Pat. No. 5,536,655; WO 00/70031; WO 05/093050), Erwinia carotovara endoglucanase (Saarilahti et al., 1990, Gene 90: 9-14), Thermobifida fusca endoglucanase III (WO 05/093050), and Thermobifida fusca endoglucanase V (WO 05/093050).

[0144]Examples of fungal endoglucanases that may be used in the present invention, include, but are not limited to, Trichoderma reesei endoglucanase I (Penttila et al., 1986, Gene 45: 253-263, Trichoderma reesei Cel7B endoglucanase I (GenBank:M15665), Trichoderma reesei endoglucanase II (Saloheimo et al., 1988, Gene 63:11-22), Trichoderma reesei Cel5A endoglucanase II (GenBank:M19373), Trichoderma reesei endoglucanase III (Okada et al., 1988, Appl. Environ. Microbiol. 64: 555-563, GenBank:AB003694), Trichoderma reesei endoglucanase V (Saloheimo et al., 1994, Molecular Microbiology 13: 219-228, GenBank:Z33381), Aspergillus aculeatus endoglucanase (Ooi et al., 1990, Nucleic Acids Research 18: 5884), Aspergillus kawachii endoglucanase (Sakamoto et al., 1995, Current Genetics 27: 435-439), Fusarium oxysporum endoglucanase (GenBank:L29381), Humicola grisea var. thermoidea endoglucanase (GenBank:AB003107), Melanocarpus albomyces endoglucanase (GenBank:MAL515703), Neurospora crassa endoglucanase (GenBank:XM_324477), Humicola insolens endoglucanase V, Myceliophthora thermophila CBS 117.65 endoglucanase, Thermoascus aurantiacus endoglucanase I (GenBank:AF487830) and Trichoderma reesei strain No. VTT-D-80133 endoglucanase (GenBank:M15665).

[0145]Examples of cellobiohydrolases useful in the present invention include, but are not limited to, Aspergillus aculeatus cellobiohydrolase II (WO 2011/059740), Chaetomium thermophilum cellobiohydrolase I, Chaetomium thermophilum cellobiohydrolase II, Humicola insolens cellobiohydrolase I, Myceliophthora thermophila cellobiohydrolase II (WO 2009/042871), Penicillium occitanis cellobiohydrolase I (GenBank:AY690482), Talaromyces emersonii cellobiohydrolase I (Gen Bank:AF439936), Thielavia hyrcanie cellobiohydrolase II (WO 2010/141325), Thielavia terrestris cellobiohydrolase II (CEL6A, WO 2006/074435), Trichoderma reesei cellobiohydrolase I, Trichoderma reesei cellobiohydrolase II, and Trichophaea saccata cellobiohydrolase II (WO 2010/057086).

[0146]Examples of beta-glucosidases useful in the present invention include, but are not limited to, beta-glucosidases from Aspergillus aculeatus (Kawaguchi et al., 1996, Gene 173: 287-288), Aspergillus fumigatus (WO 2005/047499), Aspergillus niger (Dan et al., 2000, J. Biol. Chem. 275: 4973-4980), Aspergillus oryzae (WO 02/095014), Penicillium brasilianum IBT 20888 (WO 2007/019442 and WO 2010/088387), Thielavia terrestris (WO 2011/035029), and Trichophaea saccata (WO 2007/019442).

[0147]Other useful endoglucanases, cellobiohydrolases, and beta-glucosidases are disclosed in numerous Glycosyl Hydrolase families using the classification according to Henrissat, 1991, Biochem. J. 280: 309-316, and Henrissat and Bairoch, 1996, Biochem. J. 316: 695-696.

[0148]In the processes of the present invention, any AA9 polypeptide may be used as a component of the enzyme composition.

[0149]Examples of AA9 polypeptides useful in the processes of the present invention include, but are not limited to, AA9 polypeptides from Thielavia terrestris (WO 2005/074647, WO 2008/148131, and WO 2011/035027), Thermoascus aurantiacus (WO 2005/074656 and WO 2010/065830), Trichoderma reesei (WO 2007/089290), Myceliophthora thermophila (WO 2009/085935, WO 2009/085859, WO 2009/085864, and WO 2009/085868), Aspergillus fumigatus (WO 2010/138754), Penicillium pinophilum (WO 2011/005867), Thermoascus sp. (WO 2011/039319), Penicillium sp. (WO 2011/041397), Thermoascus crustaceous (WO 2011/041504), Aspergillus aculeatus (WO 2012/125925), Thermomyces lanuginosus (WO 2012/113340, WO 12/129699, and WO 2012/130964), Aurantiporus alborubescens (WO 2012/122477), Trichophaea saccata (WO 2012/122477), Penicillium thomii (WO 2012/122477), Talaromyces stipitatus (WO 2012/135659), Humicola insolens (WO 2012/146171), Malbranchea cinnamomea (WO 2012/101206), Talaromyces leycettanus (WO 2012/101206), and Chaetomium thermophilum (WO 2012/101206).

[0150]In one embodiment, the AA9 polypeptide is used in the presence of a soluble activating divalent metal cation according to WO 2008/151043, e.g., manganese or copper.

[0151]In another embodiment, the AA9 polypeptide is used in the presence of a dioxy compound, a bicylic compound, a heterocyclic compound, a nitrogen-containing compound, a quinone compound, a sulfur-containing compound, or a liquor obtained from a pretreated cellulosic material such as pretreated corn stover (WO 2012/021394, WO 2012/021395, WO 2012/021396, WO 2012/021399, WO 2012/021400, WO 2012/021401, WO 2012/021408, and WO 2012/021410).

[0152]In one embodiment, such a compound is added at a molar ratio of the compound to glucosyl units of cellulose of about 10−6 to about 10, e.g., about 10−6 to about 7.5, about 10−6 to about 5, about 10−6 to about 2.5, about 10−6 to about 1, about 10−5 to about 1, about 10−5 to about 10−1, about 10−4 to about 10−1, about 10−3 to about 10−1, or about 10−3 to about 10−2. In another embodiment, an effective amount of such a compound is about 0.1 μM to about 1 M, e.g., about 0.5 μM to about 0.75 M, about 0.75 μM to about 0.5 M, about 1 μM to about 0.25 M, about 1 μM to about 0.1 M, about 5 μM to about 50 mM, about 10 μM to about 25 mM, about 50 μM to about 25 mM, about 10 μM to about 10 mM, about 5 μM to about 5 mM, or about 0.1 mM to about 1 mM.

[0153]In one embodiment, the one or more (e.g., several) hemicellulolytic enzymes comprise a commercial hemicellulolytic enzyme preparation. Examples of commercial hemicellulolytic enzyme preparations suitable for use in the present invention include, for example, SHEARZYME™ (Novozymes A/S), CELLIC® HTec (Novozymes A/S), CELLIC® HTec2 (Novozymes A/S), CELLIC® HTec3 (Novozymes A/S), VISCOZYME® (Novozymes A/S), ULTRAFLO® (Novozymes A/S), PULPZYME® HC (Novozymes A/S), MULTIFECT® Xylanase (Genencor), ACCELLERASE® XY (Genencor), ACCELLERASE® XC (Genencor), ECOPULP® TX-200A (AB Enzymes), HSP 6000 Xylanase (DSM), DEPOL™ 333P (Biocatalysts Limit, Wales, UK), DEPOL™ 740L. (Biocatalysts Limit, Wales, UK), and DEPOL™ 762P (Biocatalysts Limit, Wales, UK), ALTERNA FUEL 100P (Dyadic), and ALTERNA FUEL 200P (Dyadic).

[0154]Examples of xylanases useful in the processes of the present invention include, but are not limited to, xylanases from Aspergillus aculeatus (GeneSeqP:AAR63790; WO 94/21785), Aspergillus fumigatus (WO 2006/078256), Penicillium pinophilum (WO 2011/041405), Penicillium sp. (WO 2010/126772), Talaromyces lanuginosus GH11 (WO 2012/130965), Talaromyces thermophilus GH11 (WO 2012/13095), Thielavia terrestris NRRL 8126 (WO 2009/079210), and Trichophaea saccata GH10 (WO 2011/057083).

[0155]Examples of beta-xylosidases useful in the processes of the present invention include, but are not limited to, beta-xylosidases from Neurospora crassa (SwissProt:Q7SOW4), Trichoderma reesei (UniProtKB/TrEMBL:Q92458), Talaromyces emersonii (SwissProt:Q8X212), and Talaromyces thermophilus GH11 (WO 2012/13095).

[0156]Examples of acetylxylan esterases useful in the processes of the present invention include, but are not limited to, acetylxylan esterases from Aspergillus aculeatus (WO 2010/108918), Chaetomium globosum (UniProt:Q2GWX4), Chaetomium gracile (GeneSeqP:AAB82124), Humicola insolens DSM 1800 (WO 2009/073709), Hypocrea jecorina (WO 2005/001036), Myceliophtera thermophila (WO 2010/014880), Neurospora crassa (UniProt:q7s259), Phaeosphaeria nodorum (UniProt:QOUHJ1), and Thielavia terrestris NRRL 8126 (WO 2009/042846).

[0157]Examples of feruloyl esterases (ferulic acid esterases) useful in the processes of the present invention include, but are not limited to, feruloyl esterases form Humicola insolens DSM 1800 (WO 2009/076122), Neosartorya fischeri (UniProt:A1 D9T4), Neurospora crassa (UniProt:Q9HGR3), Penicillium aurantiogriseum (WO 2009/127729), and Thielavia terrestris (WO 2010/053838 and WO 2010/065448).