Инвестиции

Стартапам

Инвесторам

Инвесторам

Аналитика

Инвестиции

Стартапам

Инвесторам

Аналитика

Спрос и кооперация

Спрос и кооперация

Развитие и продвижение бизнеса

Спрос

Кооперация

Спрос и кооперация

Развитие и продвижение бизнеса

Спрос

Кооперация

Гранты и кредиты

Гранты и кредиты

Инфраструктура

Инфраструктура

Современные пространства

для бизнеса

для бизнеса

Инфраструктура

Современные пространства

для бизнеса

для бизнеса

Патентование

Патентование

Обучение и карьера

Обучение и карьера

Проекты для мегаполиса

Проекты для мегаполиса

Технологические городские проекты

Проекты для мегаполиса

О Кластере

О Кластере

Лидеры цифровой трансформации

Лидеры цифровой трансформации

Академия инноваторов

Академия инноваторов

Новатор Москвы

Новатор Москвы

Обучение и карьера

Обучение и карьера

Образовательные программы и база знаний

Обучение

Обучение и карьера

Образовательные программы и база знаний

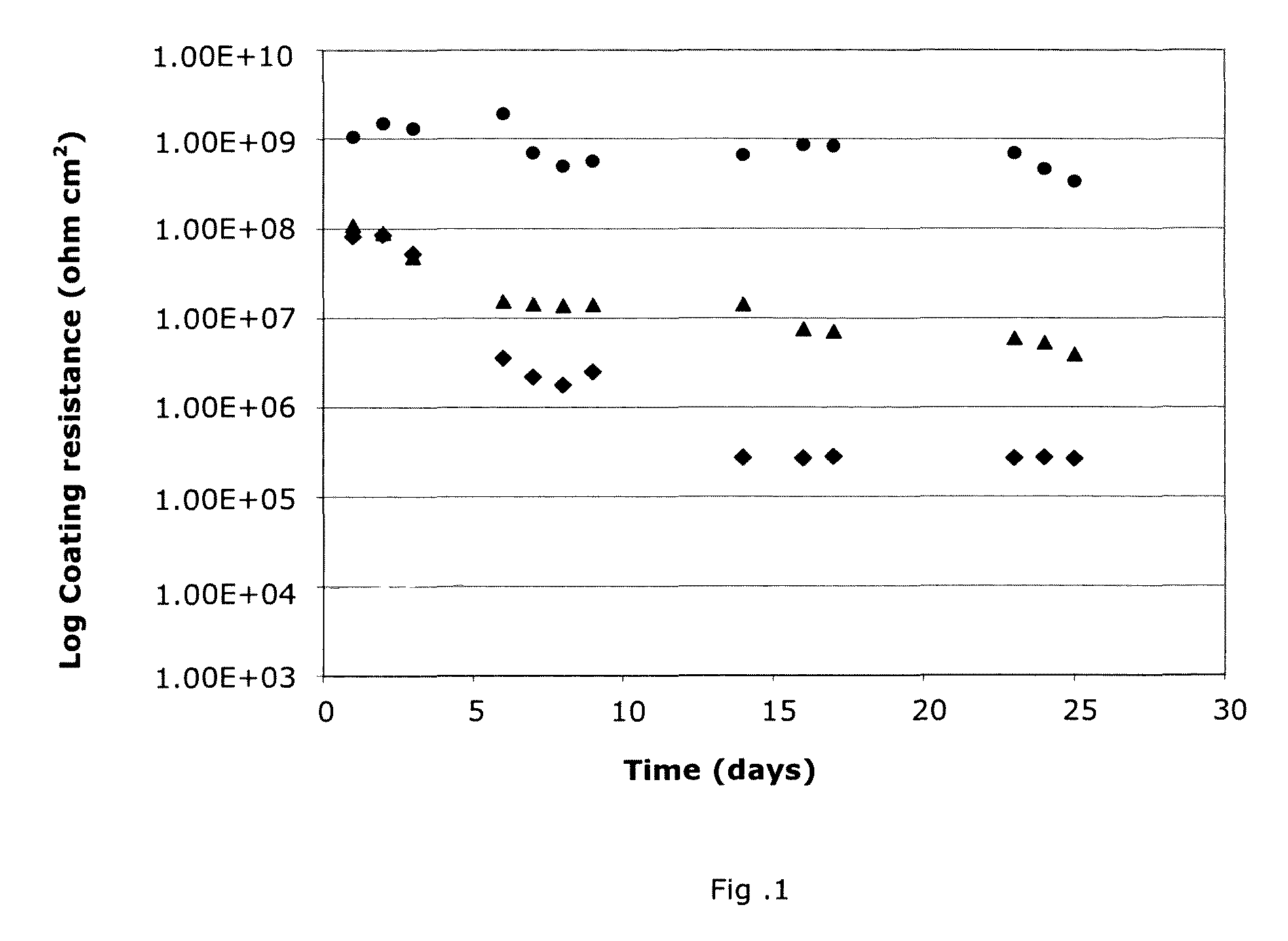

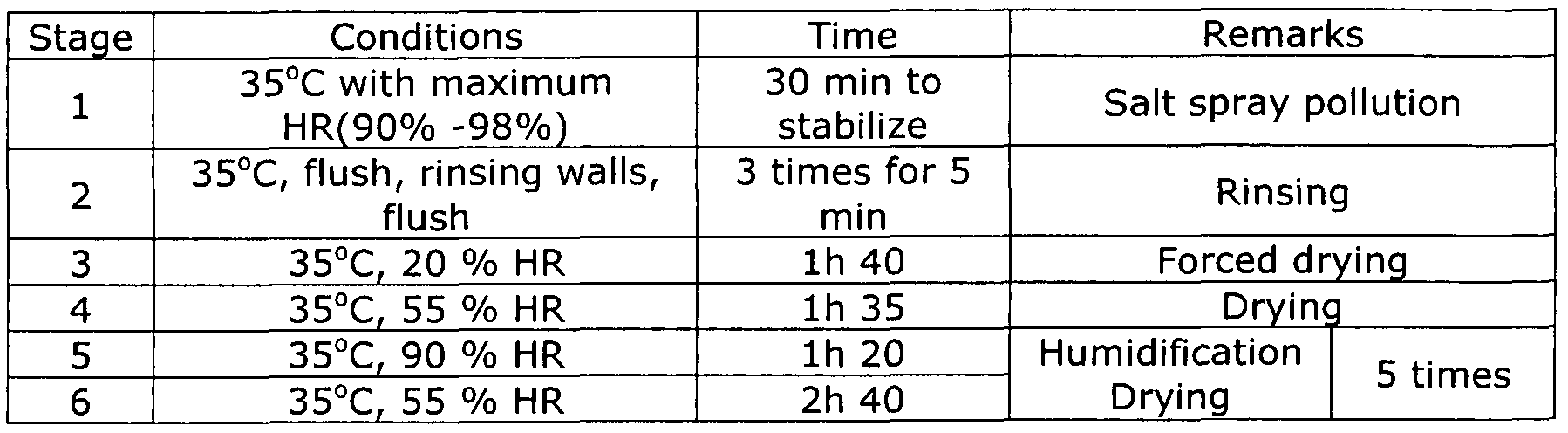

Accelerated corrosion test

Accelerated corrosion test  The test was performed in a WEISS type SC/KKT-1000 cabinet. The cabinet uses a solution of l%NaCI at pH 4 (acidified with H2S04) and a conductivity of <5 μ≤ (micro-Siemens). The results obtained after 10 weeks of the ECCl test are given in Table 4.

The test was performed in a WEISS type SC/KKT-1000 cabinet. The cabinet uses a solution of l%NaCI at pH 4 (acidified with H2S04) and a conductivity of <5 μ≤ (micro-Siemens). The results obtained after 10 weeks of the ECCl test are given in Table 4.